Behind the Scenes: How Our Socks Are Made

At Townbusiness, we take immense pride in crafting socks that combine comfort, quality, and style. Every pair of socks we produce is a testament to our dedication to excellence. Here, we invite you to take a closer look at the meticulous process behind creating our premium socks, including the innovative use of 200-needle knitting technology, our choice of high-quality materials like mercerized cotton, bamboo, and modal, and our rigorous quality control measures.

The Craftsmanship of 200-Needle Knitting

The foundation of our high-quality socks lies in the advanced 200-needle knitting machines we use. But what does 200-needle knitting mean, and why is it important?

Simply put, the number of needles in a knitting machine determines the density of the fabric. A 200-needle machine uses finer needles, allowing us to create socks with a tighter weave, smoother texture, and more intricate patterns. This technique ensures:

-

Unmatched Comfort: The finer knitting creates a soft, seamless feel, reducing the chances of irritation and enhancing overall comfort.

-

Enhanced Durability: A denser weave makes the socks more resistant to wear and tear, ensuring they stand the test of time.

-

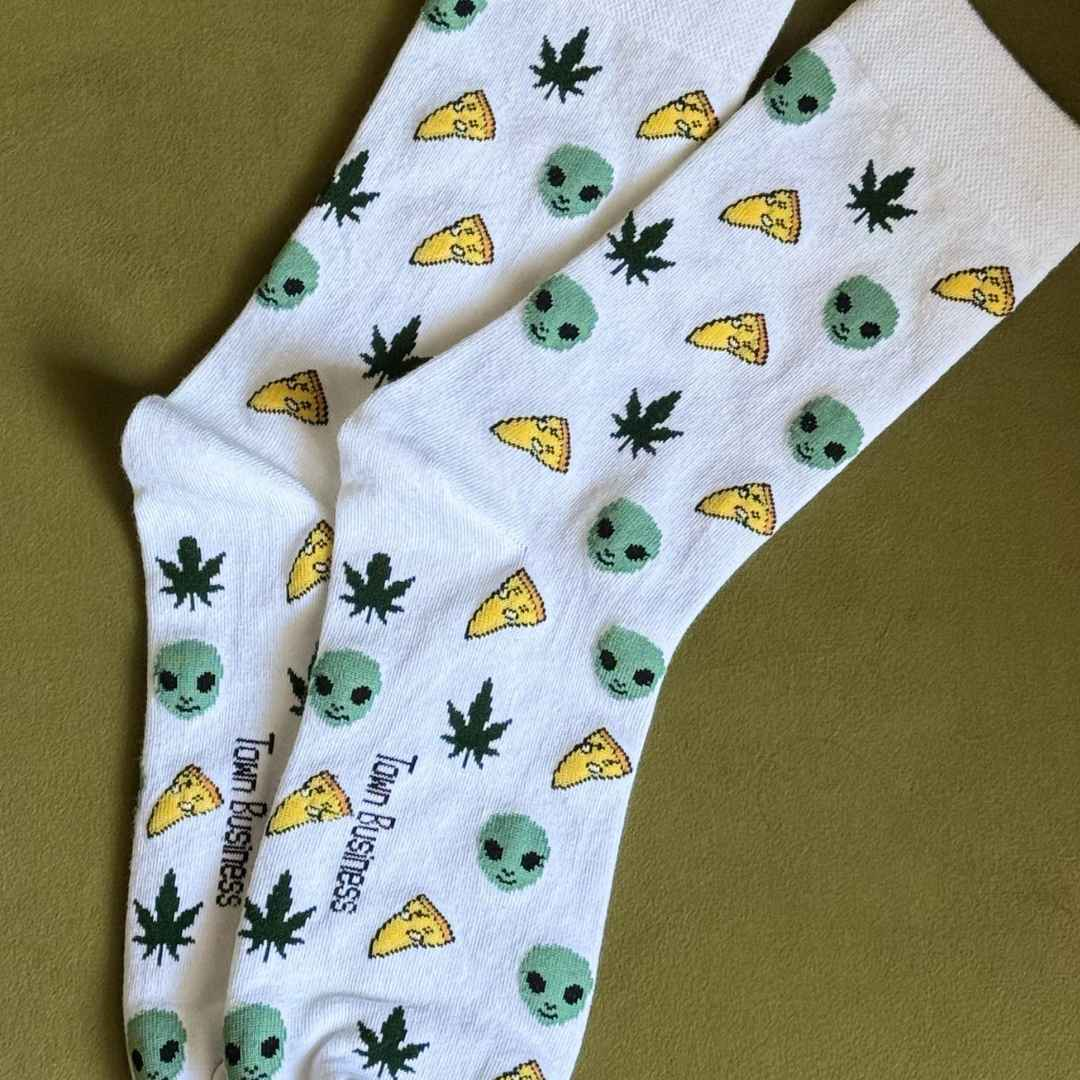

Superior Aesthetics: The fine knitting allows for precise detailing, resulting in vibrant patterns and elegant designs that set our socks apart.

Thoughtful Design and Material Selection

Before knitting begins, our design team carefully conceptualizes each pair of socks. Whether it’s a festive holiday design or a versatile everyday style, we ensure that every pattern reflects our commitment to style and functionality.

Equally important is the selection of materials. We use premium-quality fabrics like:

-

Mercerized Cotton: Known for its smooth finish and vibrant colors.

-

Bamboo Fibers: Eco-friendly, soft, and naturally antibacterial.

-

Modal: A sustainable fabric that’s breathable, silky, and durable.

These materials are chosen not only for their comfort but also for their breathability, moisture-wicking properties, and sustainability.

The Production Process

-

Pattern Programming: Once the design is finalized, it is programmed into the knitting machines, ensuring every detail is perfectly replicated.

-

Knitting: The 200-needle machines then work their magic, weaving together threads to create a flawless sock.

-

Shaping and Finishing: After knitting, the socks are shaped and finished, ensuring a snug, comfortable fit.